Structural hunhu jekiseni muforoma kuti motokari

Tsananguro Pfupi:

Zvimotokari zvikamu zvakaonda, zvakakura muhukuru, zvakakwirira mukuita uye nzvimbo zhinji dzakakombama muchitarisiko. Automobile jekiseni muforoma ine yayo chaiyo yakasarudzika hunhu.

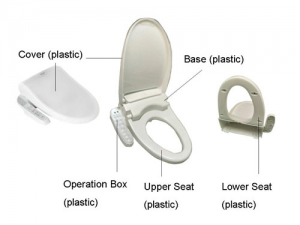

Iko kukurumidza kusimudzira kwemotokari indasitiri iri kumashure kweyemotokari kufa indasitiri. Mumotokari nyowani, zviuru zvemotokari Hardware muforoma uye angangoita mazana mashanu epurasitiki kuumbwa kwemukati mekunze nekushongedza kwekunze kunodiwa, saka pane kudiwa kukuru kweyekuumba mota.

Seri kwekubudirira kweindasitiri yemotokari ndiyo indasitiri yemumba chiganda, inonzi mai veindasitiri muChina uye simba rekupinda munharaunda yakapfuma muJapan. Munyika dzekumadokero dzakasimukira, chiGerman chiko chinonzi bhenefiti yekuwedzera. China yekuumbwa indasitiri yakagadzira kweinoda kusvika hafu yezana ramakore. Kunyanya kubva shanduko uye kuvhura, China yeforoma indasitiri yasvika yepasirese nhanho. Mundima yezvigadzirwa zvemotokari, emabhizimusi eChina emagetsi emabhizimusi akaverengera inopfuura hafu yeiyo yakazara maChinese maforoma indasitiri, uye achiramba achisimuka Zvinotendwa kuti zvigadzirwa zvemotokari zvichawanda uye zvichaburitswa mune ramangwana, uye kugadzirwa kwemaumbwe emota kuchakurumidza uye nekukurumidza.

Structural Zvinoitwa jekiseni Mould kuti Automobile

1. Kune zvakawanda zvakakura kuumbwa kwemotokari;

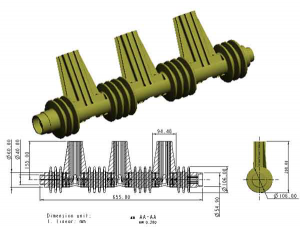

Zvimotokari zvikamu zvakakura kwazvo muhukuru uye saizi kupfuura epurasitiki zvikamu zvinowanzo shandiswa mumagetsi nemagetsi zvigadzirwa. Senge mabhomba, madhibhodhi uye madhoo pamotokari. Naizvozvo, saizi uye vhoriyamu yeforoma yekuzviita zvakare yakakura kwazvo.

2. Complex chimiro

Iyo mhango uye musimboti zvine mativi matatu: iyo yekunze neyemukati chimiro chechikamu chepurasitiki chakaumbwa zvakananga nedumbu uye musimboti.

Aya maratidziro akaomesesa matatu-matunhu anonetsa kugadzirisa, kunyanya buri gomba pamusoro pegomba. Kana iyo yechinyakare yekugadzirisa nzira ikatorwa, inoda kwete chete yakakwira tekinoroji yevashandi, akawanda anobatsira majeki, maturusi mazhinji, asi zvakare yakareba yekugadzirisa kutenderera.

3. High nemazvo;

Yakanyanya kunyatsoita uye yepamusoro pehunhu zvinodiwa, hurefu hwehupenyu hwehupenyu zvinodiwa: furu inowanzo kuverengerwa mukadzi kufa, murume kufa uye chigadziko cheforoma, mamwe anogona zvakare kuve akawanda zvidimbu zvegungano module. Iko kune iko kusanganiswa kwekumusoro uye kwakadzika kufa, iko kusanganisa kwekuisa uye mhango, uye kusanganiswa kwemamojuru kunoda yakakwira machining kunyatso. Parizvino, iyo chaiyo yekuvhenekera yezvikamu zvepurasitiki zvakawandisa inofanirwa kuve it6-7, iyo yepamusoro rough Ra 0.2-0.1μ m, iyo yakatarwa kurongeka kweinoenderana jekiseni muforoma zvikamu inodiwa kuti ive5-6, uye pamusoro roughness Ra 0.1 μ m kana zvishoma. Iko kumeso kweiyo laser disk kurekodha pamusoro kunofanirwa kuve 0.02-0.01μ m yegirazi rekugadzirisa danho, iro rinoda kuti kumeso kweforoma kuve kushoma pane 0.01 μ M.

4. Hupenyu hwakareba hwebasa.

Yakareba hupenyu jekiseni muforoma inodiwa kuti uvandudze kugona uye kudzikisa mutengo. Parizvino, hupenyu hwebasa rejekiseni muforoma kazhinji hunoda kanopfuura ka1 miriyoni nguva. Zvekujekesa jekiseni muforoma, chigayo cheforoma nekuomarara kukuru chinofanira kushandiswa, hukobvu hweforoma huchawedzerwa, uye ikholamu inotsigira kana koni yekumisikidza chinhu ichawedzerwa kudzivirira chakuvhuvhu kubva mukuremara. Dzimwe nguva kumanikidza kwemukati kunogona kusvika 100MPa. Ejection mudziyo chinhu chakakosha chinokanganisa kushanduka uye kujeka kweyakagadzirwa, saka yakanaka ejection poindi inofanira kusarudzwa kuita yunifomu yekuparadza. Mune chimiro cheiyo yepamusoro-chaiyo jekiseni muforoma, mazhinji acho anotora iko kunyorera kana kuzere kurongedza chimiro, izvo zvinoda iko kugadziriswa kunyatso uye nekuchinjana kweforoma zvikamu kuti zvinyatsovandudzwa.

5.Yakareba nzira kuyerera uye yakasimba yekugadzira nguva:

Kwezvikamu zvejekiseni, mazhinji acho zvigadzirwa zvakakwana zvinoenderana nezvimwe zvikamu, uye muzviitiko zvakawanda, zvakave zvapedzwa mune zvimwe zvikamu, zvichimirira kuenzaniswa kwezvikamu zvejekiseni kuti zvinyorwe. Nekuda kwezvakanyanya kudikanwa kwechimiro kana saizi kunyatso kwezvigadzirwa, uye nekuda kweakasiyana maficha ezve resin zvinhu, mushure mekupedza kugadzirwa kweforoma, zvinodikanwa kuyedza nekugadzirisa iyo mold kakawanda, izvo zvinoita kuti budiriro uye nguva yekuendesa ive zvakanyanya yakasimba.

6. Kugadzira nekugadzira munzvimbo dzakasiyana

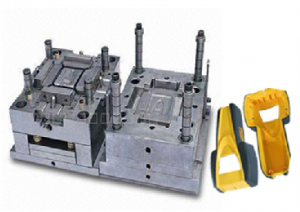

Kugadzira Mould hakusi kwekupedzisira chinangwa, asi chigadzirwa chigadzirwa chinoiswa kumberi nemushandisi. Zvinoenderana nezvinodiwa nemushandisi, fekitori vagadziri dhizaini uye inogadzira maforoma, uye kazhinji, jekiseni kugadzirwa kwezvigadzirwa kuri zvakare mune vamwe vagadziri. Nenzira iyi, dhizaini yechigadzirwa, dhizaini dhizaini uye kugadzira uye kugadzirwa kwezvigadzirwa kunoitwa munzvimbo dzakasiyana.

Yakasarudzika kupatsanurwa kwebasa, inesimba kusanganisa: iyo yekugadzira batch mumwe mugadziri ari ega, uye maitiro ekugadzira akaomarara, uye kushandiswa kweyakajairika michina uye yekuverenga manhamba ekushandisa haina kuenzana.

Unyanzvi Huru Pfungwa dzeMotokari Jekiseni Mould Dhizaini

1.Design jekiseni Kuumbwa zvikamu:

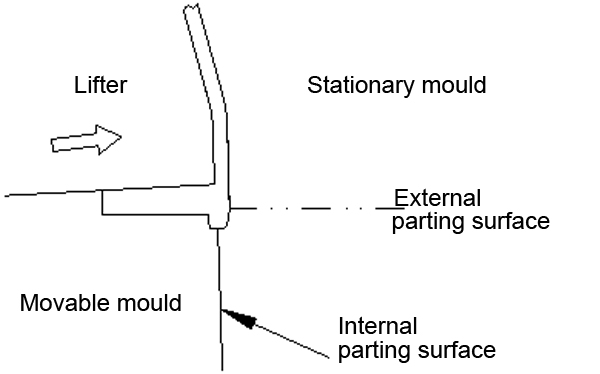

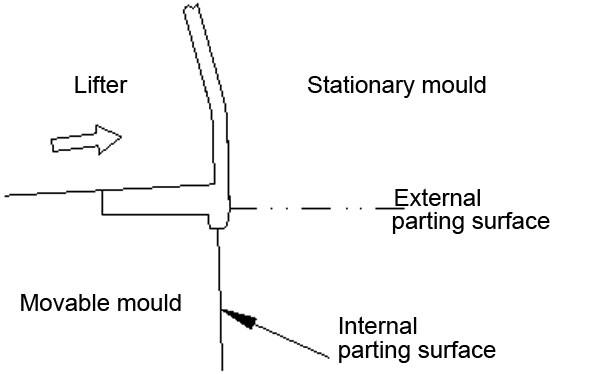

(1) Yemukati typing tekinoroji inowanzo shandiswa

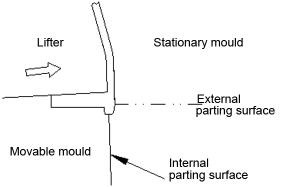

(2) Chimiro chakabatanidzwa chinowanzo gamuchirwa. .

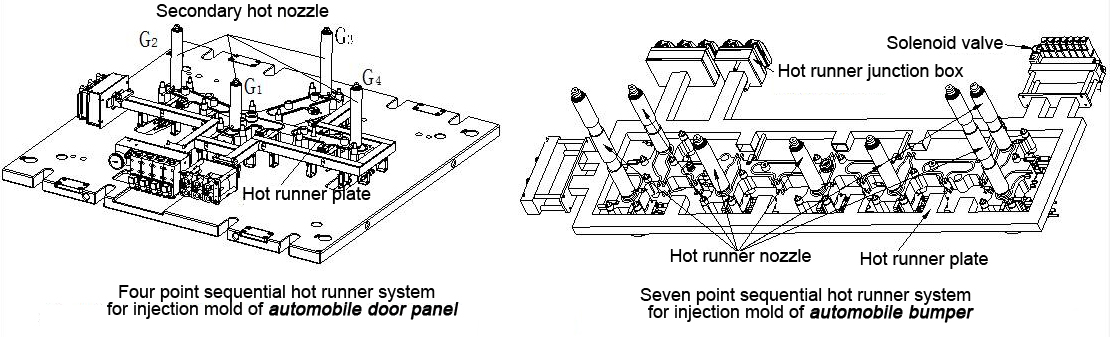

2. Gedhi system: anopisa mumhanyi anowanzo shandiswa uye kudyisa kwepurasitiki kunodzorwa neyakaenzana vharuvhu.

Kupatsanura kwemukati kwechimiro chepamberi bhamba

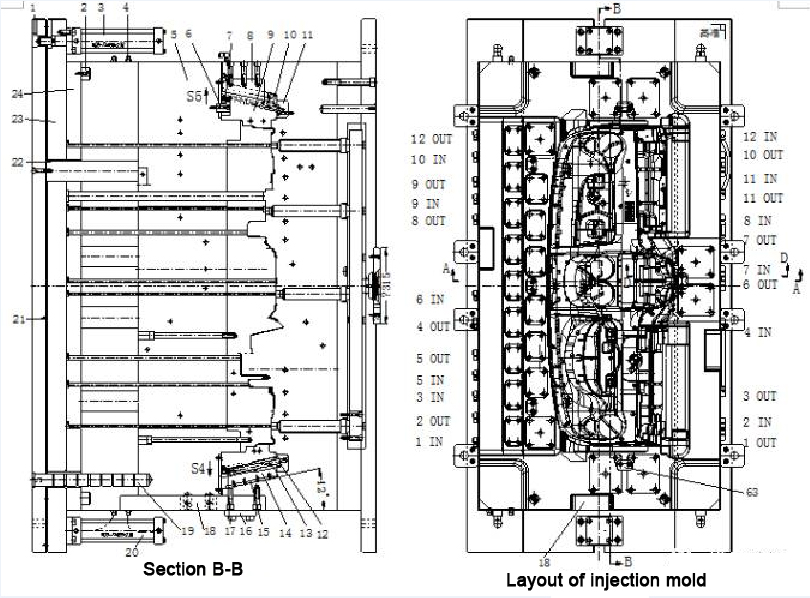

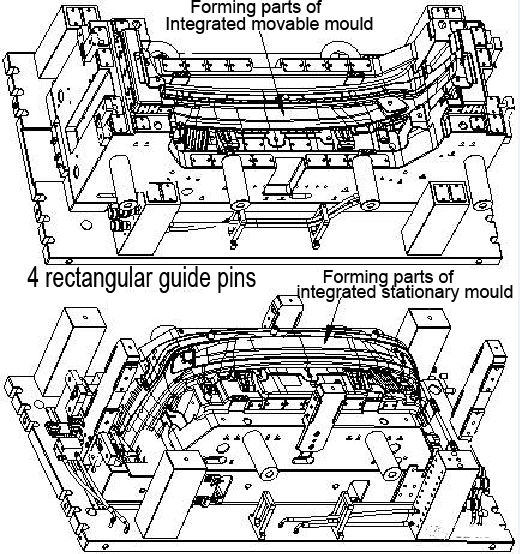

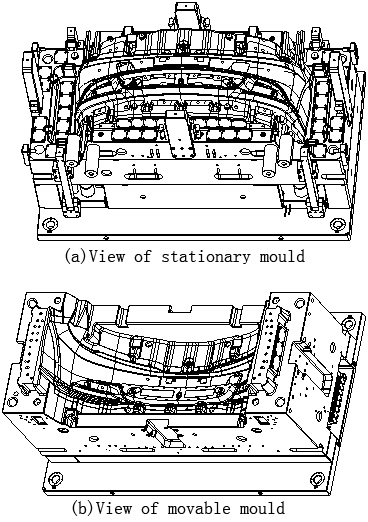

Chimiro chakabatanidzwa chinoshandiswa mumotokari plastiki muforoma

Rectangular gwara pini tekinoroji inoshandiswa mune bumper mold

Dhizaini uye kugadzirwa kwemumba mafuru ane hunyanzvi hwavo. Ndapota taura nesu kana iwe uchida kuziva zvakawanda nezve chakuvhuvhu kugadzira zvinodiwa.

Hot mumhanyi system inowanzo shandiswa mune jekiseni kuumbwa kwemota musuo panhare & mota bhamba

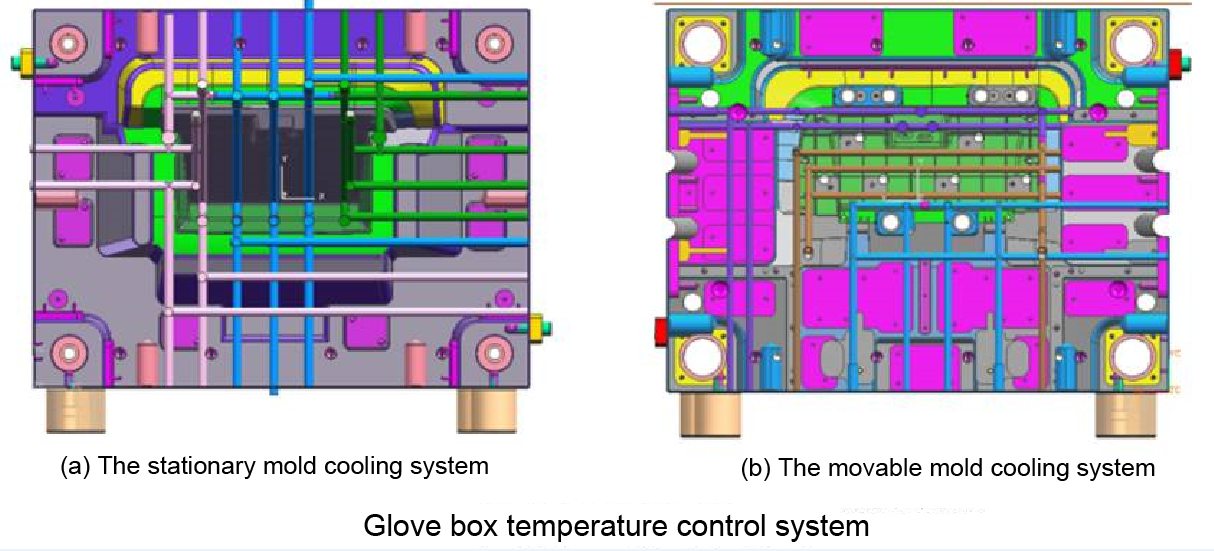

3. Tembiricha yekudzora sisitimu: kazhinji inotora fomu ye "kuburikidza nekutonhora pombi yemvura + inofarira kutonhora pombi yemvura + inotonhorera mvura mushe".

Kupisa kwekushisa sisitimu inoshandiswa mune gurovhisi bhokisi muforoma

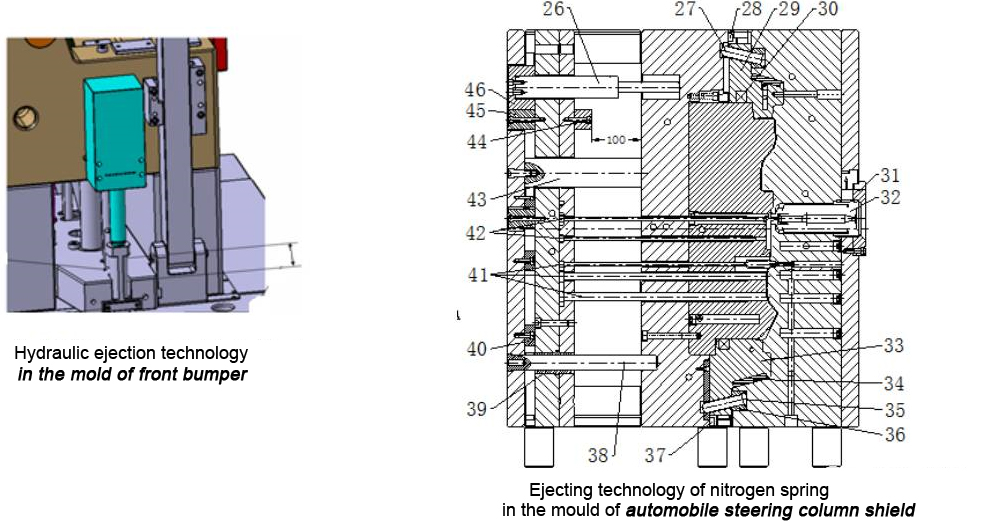

4. Demoulding system: Hydraulic ejection uye nitrogen chitubu tekinoroji dzinonyanya kushandiswa.

Hydraulic ejection uye nitrogen chitubu tekinoroji inoshandiswa muforoma dzemberi bhamba uye mota yekufambisa ikholamu nhoo

5. Inotungamira uye yekumisikidza system: rectangular gwara pini tekinoroji inowanzo shandiswa. Steering ikhombi yekuvhara muforoma kutenderera giraidhi + mativi akamira

Rectangular gwara pini tekinoroji inoshandiswa mune bumper mold

Dhizaini uye kugadzirwa kwemumba mafuru ane hunyanzvi hwavo. Ndapota taura nesu kana iwe uchida kuziva zvakawanda nezve chakuvhuvhu kugadzira zvinodiwa.