Kufa kukanda maitiro

Tsananguro Pfupi:

Kufa kukanda maitiro ndiyo nzira iyo zinc, mhangura, aluminium, magnesium, lead, tini uye lead tini alloys uye alloys avo anonyungudika pakakwirira tembiricha uye jekiseni muforoma mhango, uye ndokutonhora pasi pekumanikidzwa kuwana zvikamu.

Iko kunoshanda tembiricha yeasina-ferrous simbi kufa kukanda kwakadzikira zvakanyanya kupfuura kuya kwesimbi kukanda, uye inoenderana foundry michina uye maitiro zvinodiwa zviri nyore, uye zvidiki. Kufa kwekukanda kugadzirwa kunogona kuwana yakanakisa yepamusoro pehunhu uye kujeka kweakanyanya, kunyanya akakodzera emhando yakakura yekugadzira zvidiki uye zvepakati-zvikamu, zvinopa chikamu chakanaka rutsigiro rwemagetsi emazuva ano, midziyo yemagetsi, mota, zvigadzirwa zvekurapa, zviridzwa uye kithen zvishandiso. Simbi alloys ine mhando dzakasiyana dzakasiyana mukufa kwekukanda maitiro. Chikamu chavo chidiki uye mashoma dhizaini akasiyana, melt tembiricha tembiricha yakasiyana, kumeso kupera kwakasiyana, Saka zvakanakisa kubatanidza timu yedu yeinjiniya pakutanga panguva yekugadzira dhizaini kushandisa yedu hunyanzvi nedhizaini yekugadzira.

Pane zvinhu zvishanu zvakakosha mune yesimbi kufa kukanda maitiro:

1.Die kukanda zvinhu;

2.Types of Die vachikanda Maitiro;

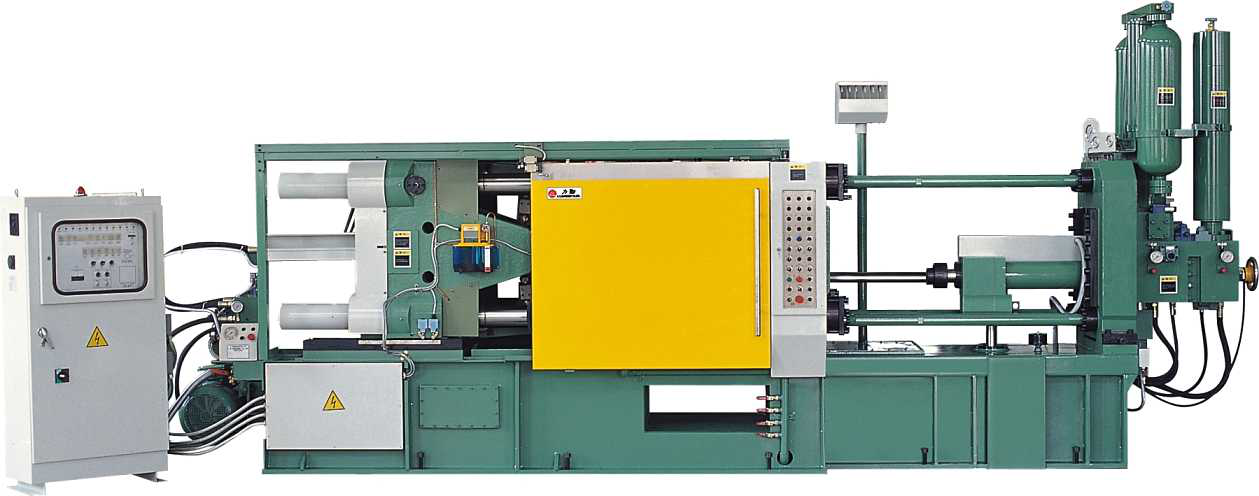

3.Die kukanda muchina;

4.Die vachikanda muforoma;

5.Post Kugadziriswa uye Kupedzisa kweAfa Kukanda Zvikamu

Simbi yekufa ichikanda maitiroinzira yekubatanidza kumanikidza, kumhanya uye nguva nekushandisa zvinhu zvitatu zvemuchina, chakuvhuvhu uye chiwanikwa. For simbi inopisa kushanda, kuvapo kumanikidzwa ndicho chikuru hunhu kufa vanofa Kudzingwa kwacho kwakasiyana nedzimwe Kudzingwa nzira. Pressure Kudzingwa inzira yakakosha yekukanda ine shoma uye isina kucheka, iyo yakawedzera nekukurumidza mune yemazuva ano simbi yekugadzira tekinoroji. Icho chiitiko chekuzadza chakuvhuvhu nesimbi yakanyungudutswa pasi pekumanikidza uye kumhanya kwakanyanya, uye kugadzira kukanda ne crystallization uye solidification pasi yakanyanya kumanikidza. High kumanikidzwa uye kumhanya ndivo hunhu hunhu kufa vachikanda. Iko kunowanzoshandiswa kumanikidza kuri makumi megapascals, kuzadza kumhanya (yemukati gedhi kumhanya) ingangoita 16-80m / s, uye nguva yekuzadza yesimbi yemvura muforoma mhango ipfupi, ingangoita 0.01-0.2s. Simbi yekufa ichikanda simbi yekurasa simbi inoratidzirwa nekumanikidza simbi yakanyungudutswa pasi pekumanikidza kwakanyanya kuva muforoma mhango. Iyo mhango mhango uye musimboti unoitwa uchishandisa yakaoma simbi inofa iyo yakavezwa muchimiro uye inoshanda zvakafanana kune jekiseni muforoma panguva yekuita. Zvichienderana nerudzi rwesimbi irikukandirwa, muchina unopisa- kana unotonhodza-kamuri unoshandiswa.

1.Die kukanda zvinhuMESTECH inopa kufa kukanda zvikamu zingi chiwanikwa, aruminiyamu chiwanikwa uye magnesium chiwanikwa. Nekuti izvi zvinhu zvitatu ndizvo zvinonyanya kushandiswa kufa kufa uchikanda chiwanikwa zvinhu panguva ino.

Zingi chiwanikwa maitiro:

--- Simba rakakwirira uye kuomarara

--- Kwakanaka magetsi kuitisa

--- Yakakwira yekupisa conductivity

--- Low mutengo mbishi zvinhu

--- Kukwirira kwepamhando yepamusoro uye kugadzikana

--- Yakanakisa yakaonda madziro kugona

--- Kugona kutonhora fomu, iyo inorerutsa kujoina

--- Yakakwira mhando yekupedzisa hunhu

--- Yakanakisa ngura kuramba - Yakazara kugadziriswazve

2.Aluminium Alloy Hunhu:

- High tembiricha dzinoshanda

--- Yakanakisa ngura kuramba

--- Chiedza

--- Simba rakanaka kwazvo uye kuomarara

--- Kugomarara kwakanaka uye simba-kusvika-uremu reshiyo

--- Yakanaka EMI uye RFI inodzivirira zvivakwa

--- Kwakanaka kupisa kupisa

--- Kwakakwira magetsi kuitisa

--- Zvakanaka kupedzisa hunhu

- Kuzadzikiswa zvizere

3. Magnesium Alloy Unhu:

--- Kwakakwira kuitisa; magetsi, uye kupisa

--- Inomira yakanyanya kushanda tembiricha

--- Kukwirira kwepamhando yepamusoro uye kugadzikana

--- Kunoshamisa matete emadziro kugona

--- Kwakanaka kwezvakatipoteredza ngura kuramba

--- Zvakanaka kupedzisa hunhu

- Kuzadzikiswa zvizere

1 Iyo Hot-Chamber Die Inokanda Maitiro

Hot-kamuri kufa kukanda, dzimwe nguva kunonzi gooseneck kukanda, ndiyo inonyanya kufarirwa yeaviri kufa kurasa maitiro. Muchiitiko ichi, iyo humburumbira kamuri yejekiseni michina yakanyudzwa mubhavhu resimbi rakaumbwa. Iyo gooseneck simbi yekudyisa sisitimu inokwevera iyo yakanyungudutswa simbi mune yefa mhango.

Kunyangwe kunyudzwa kwakananga mubhavhu rakaumbwa kunovhenekera jekiseni rekukurumidza uye nyore, zvinokonzeresa kuita kwekukora. Nekuda kweichi chokwadi, iyo inopisa-kamuri kufa yekukanda maitiro inokodzera zvakanyanya kune maficha ayo anoshandisa simbi ine yakaderera kusungunuka mapoinzi uye yakakwira fluidity. Simbi dzakanaka dzeye inopisa-kamuri kufa yekukanda maitiro inosanganisira lead, magnesium, zinc uye mhangura.

2 Iyo Cold-Chamber Inofa Inokanda Maitiro

Iyo inotonhorera-chemba kufa kufa ichikanda maitiro yakafanana chaizvo neinopisa-kamuri kufa ichikanda. Iine dhizaini inotarisa kudzikisira ngura yemuchina pane kugonesa kwekugadzira, iyo simbi yakanyungudutswa inozvitongesa- kana ruoko-yakakwenenzverwa mujekiseni. Izvi zvinobvisa kukosha kweiyo jekiseni michina yekunyudzwa mubhati resimbi yakanyungudutswa.

Kune mafomu akanyanya kuora kwekunyudza dhizaini yeanopisa-mukamuri kufa kukanda, iyo inotonhorera-kamuri maitiro inogona kuve yakanakisa imwe nzira. Aya maficha anosanganisira kukanda simbi ine yakanyanya kunyunguduka tembiricha, senge aluminium uye aluminium alloys.

3 Iyo Yakadzika-Kumanikidza Kufa Kukanda Maitiro

Yakadzika-kumanikidza kufa kukanda inzira inokodzera zvakanyanya kune zvinongedzo zvealuminium zvakaenzana zvakapoterera ekisero yekutenderera. Mota mavhiri, semuenzaniso, anowanzo gadzirwa kuburikidza neakaderera-kumanikidza kufa kukanda. Mune irwo rudzi rwekuita, chakuvhuvhu chakamira chakamira pamusoro pesimbi yakanyungudutswa yekugezesa uye chakabatana kuburikidza neye riser chubhu. Kana kamuri ikamanikidzwa (kazhinji iri pakati pe20 ne100kPa), simbi inodhonzwa kumusoro uye kupinda muforoma. Kubviswa kweanopa feeder kubva kune ino mhando yekufa kukanda maitiro kunounza yakakwira kukanda goho.

4 Iyo Vhuvhu Kufa Kukanda Maitiro

Vacuum kumanikidzwa kukanda (VPC) inguva nyowani yekufa ichikanda maitiro ayo anonunura akawedzera simba uye mashoma porosity. Maitiro aya akafanana neakaderera-kumanikidza kufa kukanda, kunze kwenzvimbo dzefa kufa kukanda muforoma nesimbi yakanyungudutswa yekugezesa inodzoserwa. Iyo cylinder kamuri inogona kuve isina chinhu, iyo inomanikidza simbi yakanyungudutswa kupinda muforoma mhango. Iyi dhizaini inoderedza kusagadzikana uye inogumira huwandu hwegasi inclusions. Vacuum kufa kukanda kunonyanya kubatsira mukushandisa kwakatemerwa post-kukanda kupisa kurapwa.

5 Iyo Squeeze Kufa Kukanda Maitiro

Dzvanya kukanda kwakagadzirwa seyunoshanda mhinduro yekukanda simbi uye alloys ine yakaderera fluidity. Mukuita uku, simbi yakanyungudutswa inozadza dhiza rakavhurika, iro rinobva rasvisvina rakavharika, zvichimanikidza simbi yacho kupinda muzvikamu zvakaomeswa zvekuumbwa. Iyo yekumanikidza yekukanda nzira inounza zvakawandisa zvigadzirwa uye inoenderana nzira yekuzotevera kupisa-kurapa. Maitiro acho anowanzo sangana nealuminium yakanyungudutswa, uye inoshandiswa mune zvinoshandiswa zvinoda kuti fiber isimbiswe.

6 Iyo Semi-Solid Inofa Inokanda Maitiro

Semi-solid kufa kukanda, dzimwe nguva kunonzi Thixoforming, ndeimwe maitiro anounza mashoma porosity uye huwandu hwakawanda. Muchina unocheka iwo wekushandira kuita madiki slugs, uye wozopisa. Kana simbi ichinge yasvika padanho rekuchinja pakati pesimba uye mvura, zvichikonzeresa kuita kwakatsetseka, sleeve yepfuti inoimanikidza kupinda muforoma mhango, uko kunoomarara. Kubatsira kweizvi kunatsiridzwa nemazvo. Isina-feri simbi senge magnesium alloy uye aluminium alloy inowanzo shandiswa neyakaomeswa-kufa kufa kukanda maitiro.

7.Mhando dzeDie Kudzingwa Maitiro

All kufa vachikanda maitiro emhando akagadzirwa aine imwecheteyo chinangwa mupfungwa-kukanda chakuvhe uchishandisa jekiseni resimbi yakanyungudutswa. Zvichienderana nerudzi rwesimbi yakanyungudika, chikamu geometry uye chikamu chemazana, akasiyana kufa kukanda maitiro anogona kuendesa akakwirira mhedzisiro pane dzimwe nzira. Mhando mbiri huru dzekufa dzichikanda mashandiro dzinopisa-kamuri uye inotonhora-kamuri kufa ichikanda. Misiyano pamhando mbiri idzi dzekufa kurasa dzinosanganisira:

Low-kumanikidzwa kufa vachikanda

Vacuum kufa vachikanda

Dzvanya ufe uchikanda

Semi-solid kufa vachikanda

1 Kupisa kumanikidza mukamuri kufa kukanda muchina

Zvinoenderana nemaumbirwo uye kamuri yekamuri, inogona kuve yakakamurwa kuita yakatwasuka uye yakatwasuka mafomu. Iyo yakakosha yesimbi yakanyungudutswa yakasungirirwa kumuchina nekamuri inopisa yekutsikirira, uye iyo pisitoni michina yesimbi hydraulic kumanikidza kupinda muforoma kunoiswa muiyo Kukuru Mukutonga kwechiFascist. Vamwe vanopisa vachimanikidza mukamuri kufa vanokanda vanoshandisa yakamanikidzwa mweya kuisa jekiseni simbi hydraulic kumanikidza kupinda muforoma isina pisitoni mashini.

Hot kamuri kufa vachikanda muchina

Iyo inopisa yekutsikirira mukamuri kufa ichikanda muchina inowanzo shandiswa kufa-vachikanda chiwanikwa ine yakaderera utsotso poindi, senge zinc, Magnesium uye tini.

2 Cold kudzvanywa kamuri kufa ichikanda muchina

Inonyungudutsa simbi kunze kwemuchina uye nekuwedzera iyo simbi yemvura mukamuri yekumanikidza ine chipunu inogona kukamurwa kuita yakatwasuka chando kamuri kufa muchikanda muchina uye yakatwasuka kamuri inotonhorera kufa muchikanda muchina zvinoenderana nekutungamira kwekufamba kweye compression pisitoni.

Iyo simbi yemvura inobviswa kubva muvira reiyo yakatwasuka inotonhora yekudhinda mukamuri kufa ichikanda muchina uye ndokudururwa mukamuri yekumanikidza. Iyo simbi iri hydraulic yakatsimbirirwa muchimiro ne compression pisitoni, uye iyo yakasara simbi inosundirwa kunze neimwe piston.

Cold kamuri vanofa vachikanda muchina

Cold kamuri vanofa vachikanda muchina

Iyo yakatwasuka inotonhorera kamuri kufa ichikanda muchina yakafanana neiya yakatwasuka, asi kufamba kwepisitoni kwakatwasuka. Mazhinji mazuva ano michina yekufa yekukanda yakatwasuka. Cold-kamuri kufa-kukanda michina inogona kufa-kukanda yakakwira yakanyunguduka simbi simbi kana nyore oxidized simbi, senge aluminium, mhangura alloys, nezvimwe.

3.Die kukanda muchina.

Die vachikanda muchina unoshandiswa kumanikidza kukanda muchina. Inosanganisira maviri marudzi anopisa ekudzvanya mukamuri kufa kurasa muchina uye kutonhora kudzvanya mukamuri kufa kurasa muchina. Iyo inotonhora inodzvanya kamuri kufa ichikanda muchina yakakamurwa kuita maviri marudzi: yakatwasuka uye yakatwasuka. Iyo simbi yakanyungudutswa inojowa muforoma nemuchina wekufa-uchikanda pasi pechiito chekumanikidza kwekutonhora nekuumba, uye iyo yakasimba simbi castings inogona kuwanikwa mushure mevhu rakavhurwa.

Hot kamuri kufa vachikanda muchina

Cold kamuri vanofa vachikanda muchina

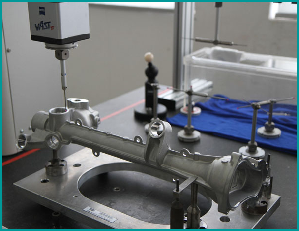

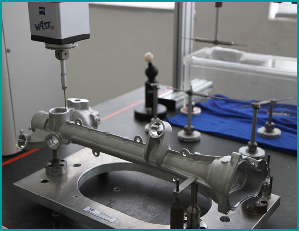

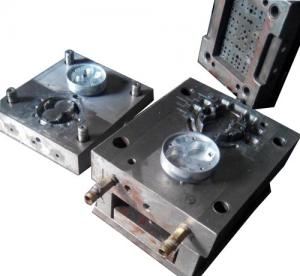

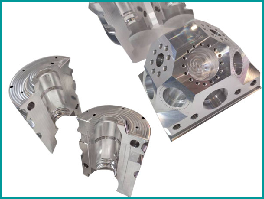

4.Die vachikanda muforoma

In siyana anoumba, ari kushanda ezvinhu kufa vanofa Kudzingwa vanofa vari pane nehasha. Kufa kukanda kuita simbi yakanyungudutswa izere neforoma mhango pasi yekumanikidza uye kumhanya, uye kusangana nesimbi inopisa kakawanda panguva yekushanda. Naizvozvo, kufa kukanda muforoma kunodiwa kuve neakanyanya kudziya kwekuneta kuramba, kupisa kupisa uye kupfeka kuramba, ngura kuramba, kukanganisa kuomarara, kuomarara kutsvuku, kudonhedza kwakanaka uye zvichingodaro. Naizvozvo, pamusoro pekurapa tekinoroji yefa yekukanda kufa inoda tekinoroji yepamusoro.

Die vachikanda muforoma

5.Post Kugadziriswa uye Kupedzisa kweAfa Kukanda Zvikamu

Isu tinopa zvakanyanya kutumira uye kupedzisa masevhisi ezve kufa zvikamu kubva kune vatinoshamwaridzana navo:

Services

Cnc machine - yakamira, yakatwasuka, kutendeuka, 5-akabatana

Kupfekedza Upfu

Liquid bemhapemha

EMI - RFI Kuchengetedza

Kuisa - chrome, mhangura, zinc, nickel, tini, goridhe

Anodizing, Magetsi Kuputira, Chromating / Isiri-chromating

Kurapa kwekupisa, Passivation, Tumbling

Graphics

Imba yeArtwork Maitiro

Silk Kuongorora

Pad Kudhinda

Bead nenyunje

Chiedza Mechanical Assembly, inosanganisira stud uye helicoil inoisa, O-mhete, gasket

Laser Kucheka uye achiita zvokutemera

Etching

Magetsi Kuputira & Silk Kuongorora