Kugadziriswa kwesimbi (simbi), irwo rudzi rwekugadzirisa tekinoroji uye zviitiko zvekugadzira zvekugadzira zvinyorwa, zvikamu uye zvikamu kubva kuzvinhu zvesimbi.

Zvikamu zvesimbi zvinoshandiswa zvakanyanya mumakina akasiyana siyana nemidziyo. Simbi simbi ine iyo yakaenzana kugadzikana, simba uye kuomarara, yakakwira uye yakadzika tembiricha yekudzivirira hunhu uye kuitisa, izvo zvinowanzo shandiswa kugadzira zvakakwana zvikamu. Inofananidzwa nemapurasitiki zvikamu, kune akawanda marudzi ezvigadzirwa zvesimbi zvikamu, senge aruminiyamu chiwanikwa, mhangura chiwanikwa, zinc chiwanikwa, simbi, titanium chiwanikwa, magnesium chiwanikwa, nezvimwewo, zvine akasiyana zvivakwa. Pakati pavo, ferroalloy, aluminium alloy, mhangura chiwanikwa uye zinc alloy zvinonyanya kushandiswa mumaindasitiri uye ehurumende zvigadzirwa. Izvi zvinhu zvesimbi zvine akasiyana epanyama uye emakemikari zvivakwa, zvakasiyana chimiro uye chimiro chesimbi simbi yekugadzirisa tekinoroji ine musiyano mukuru.

Maitiro ekugadzirisa makuru esimbi zvikamu ndeaya: machining, stamping, kunyatso kukanda, hupfu simbi, simbi jekiseni kuumbwa.

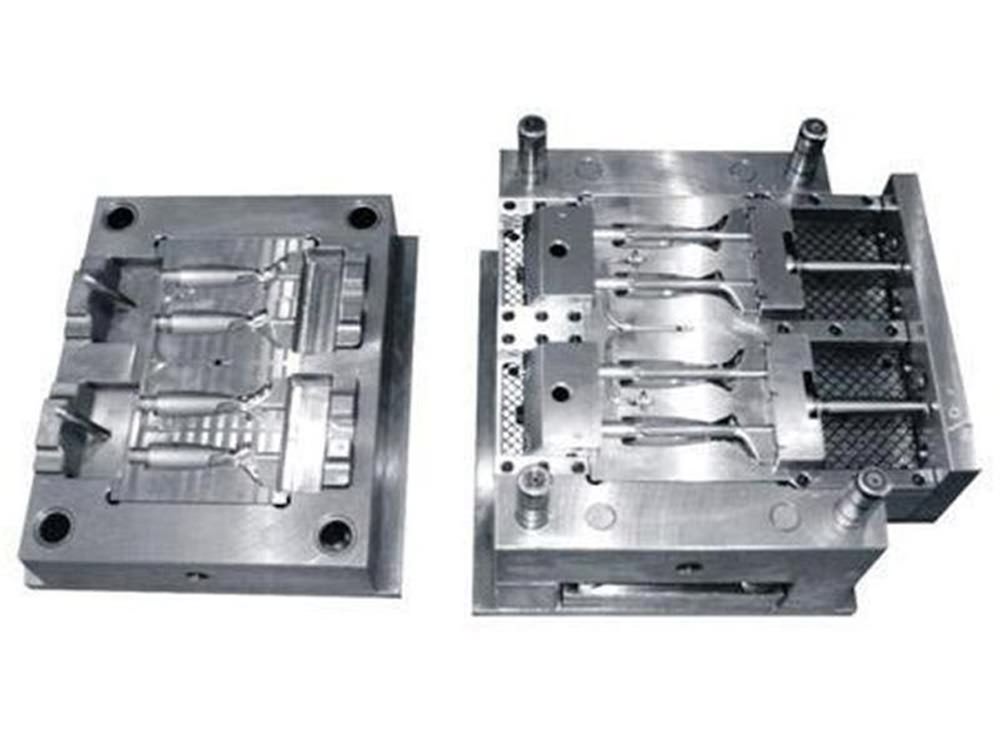

Machining ndiwo maitiro ekushandura iyo yakazara dhizaini kana mashandiro eiyo workpiece kuburikidza nerudzi rweanogadzira michina. Zvinoenderana nemusiyano mukugadzirisa nzira, inogona kukamurwa kuita yekucheka uye yekumanikidza machining. Tsikwa rudzi rwekuumba yekugadzirisa nzira iyo inoshandisa yekudhinda uye kufa kuti ishandise simba rekunze pane pepa, ubvise, pombi uye chimiro kuburitsa deformation yepurasitiki kana kupatsanurwa, kuti uwane chimiro chinodiwa uye saizi yeiyo workpiece (yekutsika chikamu).

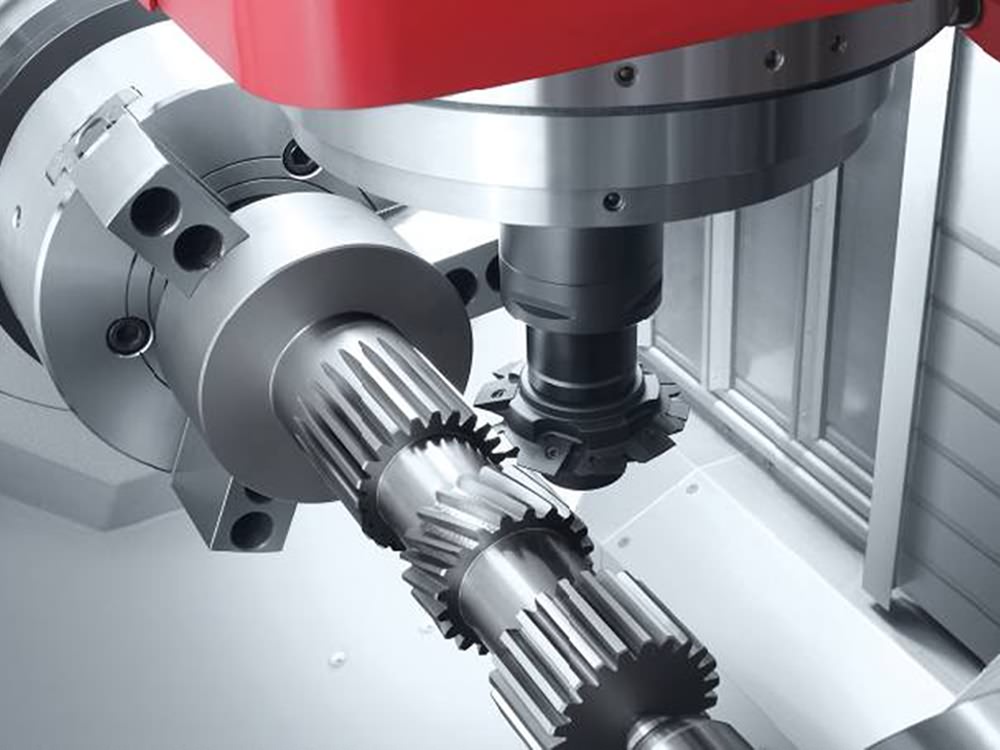

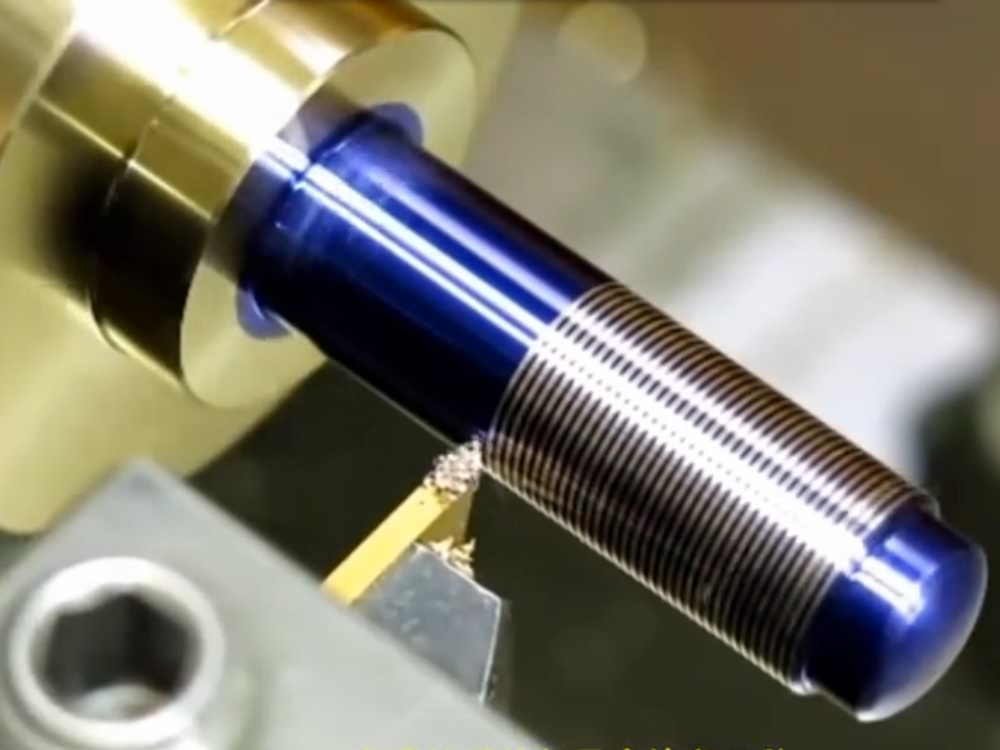

Zvakakwana kukanda, upfu simbi uye simbi jekiseni kuumbwa ndezvipi zvinopisa zvinoshanda maitiro. Ivo vanoumbwa muforoma mhango nekupisa simbi yakanyungudutswa patembiricha yepamusoro kuti vawane chinodiwa chimiro uye saizi. Kune mamwe zvakare akakosha machining, akadai se: laser machining, EDM, ultrasonic machining, electrochemical machining, chidimbu chedanda machining uye ultra-yakakwira kumhanya machining. Turning, azvikuya, nokuchengetedza, Kudzingwa, kukuya, CNC machine, CNC machine. Dzese ndedzekugadzira.

Machine maturusi ekugadzira simbi

Machine maturusi ekugadzira simbi

Mugodhi machine - Center lathe

Kubuditsa magetsi magetsi -EDM

Nemazvo sikuruwa machine

Die vachikanda muchina

Die vachikanda vanofa

Punching muchina

Tsikwa ufe

Ratidza simbi zvikamu:

1. Ferrous simbi zvikamu: zvikamu zvakagadzirwa nesimbi, chromium, manganese uye yavo alloy zvinhu.

Nemazvo muforoma zvikamu

Cnc machine psac simbi

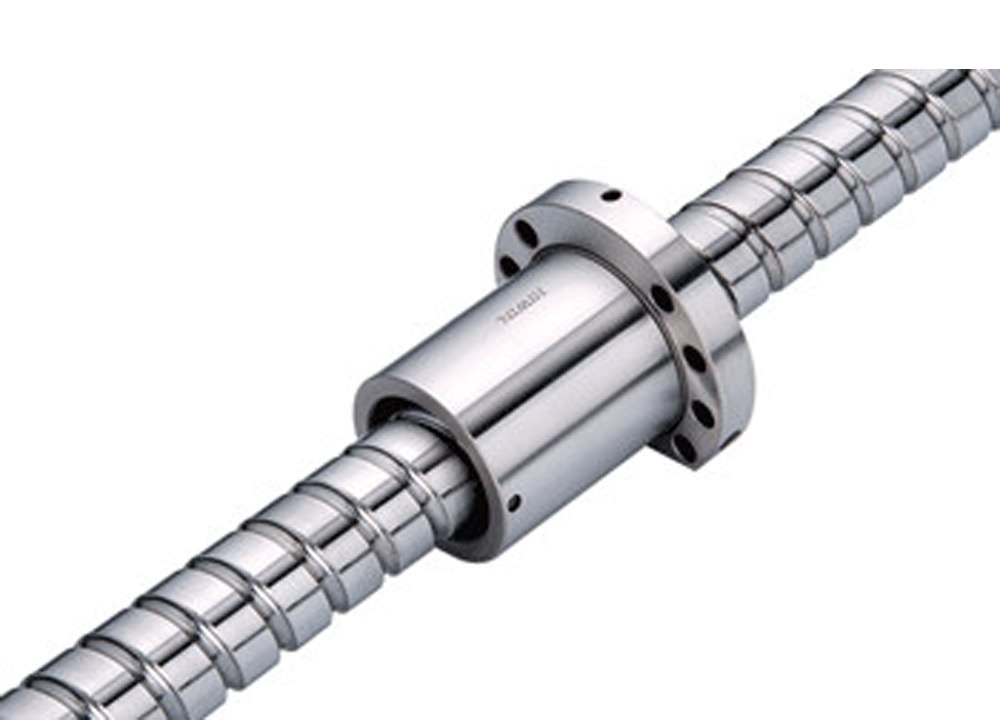

Nemazvo kutungamira sikuruu

Zvikamu zveGear transmission

2. Nonferrous simbi zvikamu: zvakajairika nonferrous alloys anosanganisira aruminiyamu chiwanikwa, mhangura chiwanikwa, magnesium chiwanikwa, nickel chiwanikwa, tini chiwanikwa, tantalum chiwanikwa, titanium chiwanikwa, zinc chiwanikwa, molybdenum chiwanikwa, zirconium chiwanikwa, nezvimwewo.

Brass magiya

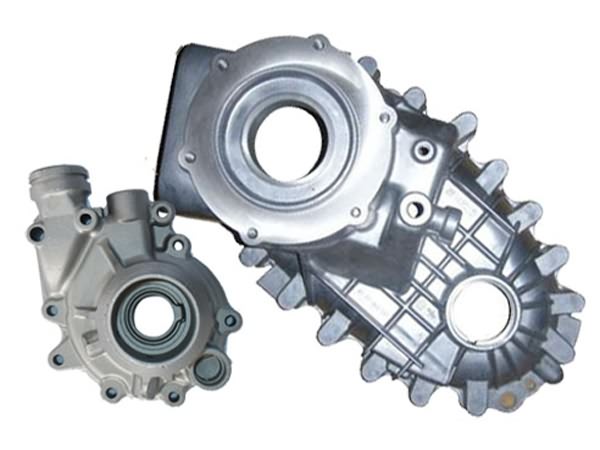

Zinc kufa kukanda dzimba

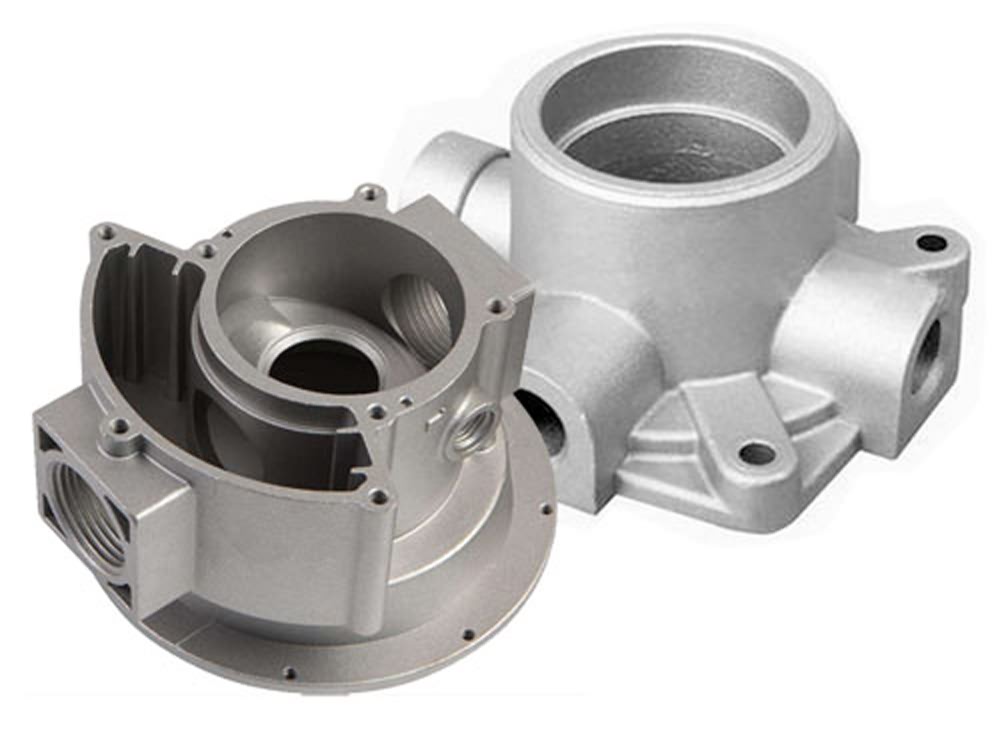

Aluminium yekudonha chivharo

Aluminium kufa kukanda dzimba

Kurapa kwepamusoro kunogona kuganhurwa muzvikamu zvina

1. Mechanical pamusoro kurapwa: sandblasting, bara nenyunje, makorari, rinopfungaira, makorari, kukwesha, spraying, kupenda, oiling, etc.

2. Kemikari pamusoro pekurapwa: bluing nekusviba, phosphating, pickling, electroless plating yesimbi dzakasiyana siyana uye alloys, kurapwa kweTD, QPQ kurapwa, kemikari oxidation, nezvimwe.

3. Electrochemical pamusoro kurapwa: anodic oxidation, electrochemical makorari, electroplating, nezvimwe.

4. Yemazuva ano ekurapwa kwepasi: makemikari mhute deposition CVD, panyama mweya deposition PVD, ion kuiswa, ion ra, kurira kwepasira laser, nezvimwe.

Mestech inopa vatengi dhizaini uye yekugadzira yezvinhu zvesimbi zvinosanganisira simbi, aluminium alloy, zinc alloy, mhangura chiwanikwa uye titanium chiwanikwa. Ndapota taura nesu kana zvichidiwa.